VALIDATION OF VERTICAL AUTOCLAVE EQUIPMENT ID – ------

PROTOCOL CONTENTS

|

S. No. |

Description |

Page No. |

|

1.0 |

Protocol approval |

3 |

|

2.0 |

Overview |

4 |

|

2.1 |

Objective |

4 |

|

2.2 |

Purpose |

4 |

|

2.3 |

Scope |

4 |

|

3.0 |

Responsibility

and Validation team |

4 |

|

4.0 |

Training |

5 |

|

5.0 |

Equipment/System

description |

5 |

|

6.0 |

Validation Procedures |

6 |

|

6.1 |

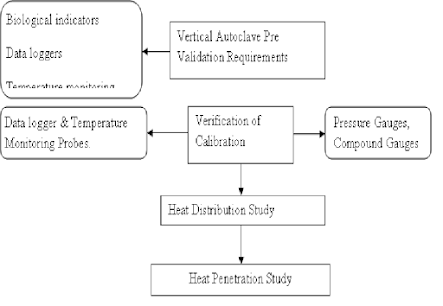

Flow charts |

6 |

|

6.2 |

Validation

Matrix |

7 |

|

6.3 |

Pre –

validation test requirements |

7 |

|

6.4 |

Verification

of Calibration of gauges |

8 |

|

6.5 |

Empty Chamber

Heat Distribution Studies |

8 |

|

6.6 |

Loaded Chamber

Heat Penetration Studies |

10 |

|

6.7 |

Developmental Approach |

15 |

|

7.0 |

Discrepancy and corrective action report |

14 |

|

8.0 |

References |

14 |

|

9.0 |

Summary |

14 |

|

10.0 |

Conclusions |

15 |

|

11.0 |

Attachment |

15 |

|

12.0 |

Revalidation

Criteria |

15 |

|

13.0 |

Revision History |

16 |

|

Signing

of this approval page of protocol indicates agreement with the qualification

approach described in this document. If any modification in the equipment

qualification approach becomes necessary, a revision through change control

shall be prepared, checked and approved. This protocol cannot be executed

unless approved by following personnel. |

|||

|

Department |

Name |

Designation

|

Signature /Date |

Prepared by

|

|||

|

Microbiology |

|

|

|

|

Quality

Assurance |

|

|

|

Reviewed by

|

|||

|

HOD-Engineering |

|

|

|

|

HOD-Production |

|

|

|

|

HOD-Microbiology |

|

|

|

|

Quality

Assurance |

|

|

|

Authorised by

|

|||

|

HOD –

QA |

|

|

|

2.0

Overview

The Vertical autoclave is used to

decontaminate the media containing petri-plates, bottles, sterility canisters

and the media test tubes before media discard.

This

protocol is designed to establish sufficient data, to assure that the Vertical Autoclave

(QCVAC-01) is suitable for decontaminating the defined load patterns when

operated in accordance with the established standard operating procedure as per

SOP.

2.2

Purpose

The

purpose of this protocol is to help the operating personnel to plan the

validation activities so as to demonstrate that the vertical autoclave operates

consistently to decontaminate the media and there are no remaining microbes

alive in the media (which is to be discarded).

2.3

Scope

This Performance Qualification

Protocol is applicable for the Laboratory Vertical Autoclave (QCVAC-01)

installed in Microbiology section at ----------

3.0

Responsibilities

and validation team

Responsibilities: The

group comprising of representatives from each of the following departments and

they shall be responsible for the overall compliance with this protocol.

Department

|

Responsibility

|

|

Engineering & Utility

|

Arranging for execution and recording of the

following activities

|

|

|

·

Calibration of gauges and

instruments ·

Periodic calibration of data

logger during validation ·

Review of protocol and report ·

Coordination with validation

activities and maintaining records. |

|

|

|

Microbiology |

· Execution and collection of data. · Participate and provide the necessary support

for the validation. · Carryout

the analysis of the Biological indicators. · Review of Protocol by department HOD/ In

charge |

|

Out side contractor

|

· Participate

and Provide necessary support for the validation activity

(as applicable). |

|

Quality

Assurance

|

· Verifying

the compliance of existing procedures to the outcome of validation. · Preparation,

Review of protocol and report. · Provide

training to concern personnel on the execution of validation activities. · HOD

is responsible for final approval of protocol and report. |

|

4.0

Training

The validation team member shall be

trained on the protocol execution of validation activity and report compilation.

The

training record shall be attached.( format No.QAGN006/F08)

5.0

Equipment Description

5.1

Equipment Detail:

|

Equipment

Name |

Vertical Autoclave |

|

Make |

Equitron |

|

Serial

Number |

7431FA.14B |

|

Equipment

ID |

QCVAC-01 |

|

Location |

Microbiology Lab |

5.1.1

Vertical Autoclave is used for the

Decontamination of used materials in microbiology area.

5.1.2

Vertical Autoclave is Vertical

cylindrical vessel, it can be operated in auto mode and having the jacketed

chamber with one round lid. As per defined load pattern, objects, which are to

be decontaminated, should be loaded vertically.

5.2

Working

Principle

5.2.1

The steam is prepared by pouring

purified water into the autoclave upto the Heater cover X stand inside. This

prepares steam at 121ºC.

5.2.2

This cycle is controlled by a Microprocessor

which controls the heating coil when the temperature goes above set temperature

range.

5.2.3

The Vertical autoclave has one

temperature sensor which controls the functioning.

6.0

Validation Test Procedures

6.1

Flow

Chart

6.2 Validation

Matrix

6.2.1 Frequency of periodic monitoring is

1Year ± 30Days

6.2.2 The following test matrix is

prepared for the Periodic Monitoring and

Periodic Monitoring of Autoclave cum

Bung Processor.

Sr. No. |

Test Description |

Periodic

Monitoring |

|

|

Performance

Qualification |

Revalidation |

||

|

No. of Cycle |

No. of Cycle |

||

|

|

Developmental Run* |

1 |

1 |

|

|

Empty chamber Heat Distribution Study |

3 |

1 |

|

|

Loaded Chamber

Heat Penetration Study |

||

|

|

a)

Petriplate and

Bottle Load |

3 |

1 |

|

|

b)

Test Tube and

Bottle Load |

3 |

1 |

* Incase of new load introduction one

developmental run shall be taken.

Note: - Any Change in Load

pattern/process/items three consecutive run are required successful validation.

6.3

Pre-validation

test requirements:

6.3.1

Following instruments shall be

required for the validation of Vertical autoclave used in the Microbiology Area.

·

Calibrated data loggers

·

Calibrated Temperature mapping

probes.

·

Geobacillus

stearothermophillus i.e. Biological Indicator Strips/Ampoules

6.3.2

The Decontamination autoclave shall

be qualified after verification of the documented evidence (obtained as per the

methods outlined in this protocol) assuring that the equipment is meeting the

desired performance attributes consistently.

6.3.3

The following pre-validation tests

shall be performed:

|

S. No. |

Description of

Activity |

Frequency |

|

1. |

Verification of calibration status of various

Instruments associated with Decontamination Autoclave. |

Before

start of the Validation activity. |

|

2. |

Verification of calibration status of data Logger

& sensors |

Before

start of the Validation activity. |

6.4

Verification

of calibration of gauges and Instruments:

6.4.1

It is necessary to verify and ensure

the Calibration status of Gauges and instruments, before carrying out

validation tests.

|

Instrument |

Range |

I.D.

No. |

Location |

Calibrated Date |

Next Due Date |

|

Pressure

Gauge |

2.1 Kg/cm²; 0 – 30 psi |

QCVPG-01 |

Lid of Autoclave |

|

|

|

Temperature

Controller |

0 – 150 ºC |

QCVTC-01 |

With HMI |

|

|

|

Temperature Sensor |

0 – 150 ºC |

QCVTS-01 |

With HMI |

|

|

|

Data

logger |

|

|

|

|

|

|

Data

logger & Sensors in loop |

|

|

|

Pre- Calibration |

Post- Calibration |

|

|

|

6.4.2

Testing and measuring instruments

related to equipment shall be verified, recorded in the report for the

verification of their calibration status.

6.5

Empty Chamber Heat Distribution

Studies

6.5.1.1

The

Autoclave is capable of attaining a temperature of 121.1°C during the decontamination

hold period of 30 minutes.

6.5.1.2

Analyze

the temperature profile and identify the cold spot.

6.5.2.1

Set

the temperature of 122°C for 30 minutes decontamination cycle.

6.5.2.2

Prepare

at least 06 Nos. calibrated temperature mapping probe with location and channel

tag.

6.5.2.3

Pass

06 No. temperature mapping probe into chamber through the validation port of

the Autoclave. Seal the port with

silicone sealant so that steam leakage does not take place. Suspend the probes in the chamber in

different position as per the drawing no. 1 and ensure that probes do not touch

any metallic surface.

6.5.2.4

Connect

the probes to a suitable data logger, which can scan and print the actual

temperature observed at different locations with respect to time.

6.5.2.5

Operate

the Vertical Autoclave as per SOP No. QC-SP-340.

6.5.2.6

The

decontamination hold time for an empty chamber shall be 30 minutes.

6.5.2.7

Start

the data logger to record actual temperatures within the decontamination

chamber with respect to time at a scan time of NMT 15 sec interval.

6.5.2.8

After

completion of cycle connect the data logger to the computer system and download the

data and calculate Fo value of each temperature mapping location.

6.5.2.9

Compile

the data generated during the qualification test for a complete evaluation of the

system.

6.5.2.10 Prepare summary and conclusion of the performance qualification test, which will be finally approved by Head - Quality Assurance.

6.5.3

Acceptance Criteria

6.5.3.1

The

temperature at each temperature mapping probe should be within the range of 121.1°C

to 124°C during the decontamination hold period of 30 min.

6.5.3.2

The

minimum Fo should be 30 min (based on process lethality during the decontamination

cycle).

6.5.3.3

The

pressure during decontamination hold period should be 1.1 - 1.2 Kg/cm².Observation

and Result

6.5.3.4

d

6.6

Loaded Chamber Heat Penetration

Studies

6.6.1

Objective

6.6.1.1

The

Autoclave is capable of attaining a temperature of 121.1°C within the defined

loads during the decontamination hold period of 30 minutes.

6.6.1.2

Find

out the cold spot if any.

|

Sr. No. |

Load Description |

Material |

Quantity (Maximum Load) |

|

1 |

Petri

plate and bottle Load (Media

Load- 1) |

Petriplate |

Full Autoclavable

bag (80 nos.) |

|

Bottles |

05

Nos. |

||

|

Spreader |

10

Nos. |

||

|

10

ml Test tubes (Small) |

1

Stand (40 nos) |

||

|

Tips |

1

Box (50 tips) |

||

|

Sterility

Canisters |

10

Box |

||

|

2 |

Test

Tubes and bottle load (Media

Load- 2) |

100

ml Test Tubes (Large) |

2

Full Stand (20 nos. Each) |

|

Bottles |

05

Nos. |

||

|

Spreader |

10

Nos. |

||

|

10

ml Test Tubes (Small) |

1

Stand (40 nos) |

||

|

Tips |

1

box (50 tips each) |

||

|

Sterility

Canisters |

10 |

6.6.3

Procedure

6.6.3.1

Set

the temperature of 122°C for 30 minutes decontamination cycle.

6.6.3.2

Prepare

at least 06 Nos. calibrated temperature mapping probe with location tag.

6.6.3.3

Load

the chamber Pass 06 No. temperature mapping probe into chamber through the

validation port of the Autoclave. Seal

the port with silicone sealant so that steam leakage does not take place. Suspend the probes in the chamber in

different position as per the photographic representation and ensure that

probes do not touch any metallic surface.

6.6.3.4

Connect

the probes to a suitable data logger, which can scan and print the actual

temperature with respect to time.

6.6.3.5

Attach

the Biological Indicators to each probe as per the drawing no. 2

6.6.3.6

Operate

the Vertical Autoclave as per SOP No. QC-SP-340.

6.6.3.7

The

decontamination hold time for loaded chamber heat penetration shall be 30

minutes.

6.6.3.8

Start

the data logger to record actual temperatures within the decontamination

chamber with respect to time at a scan time of NMT 15 sec interval.

6.6.3.9

After

completion of cycle connect the data logger to computer system and download the

data and calculate Fo value of each temperature mapping location.

6.6.3.10

Compile

the data generated during the qualification test for complete evaluation of the

system.

6.6.3.11

Prepare

summary and conclusion of the performance qualification test, which will be

finally approved by Head - Quality Assurance.

6.6.4.1

The

temperature at each temperature mapping probe inside the load should be within

the range of 121.1°C to 124°C during the decontamination hold period of 30 min.

6.6.4.2

The

minimum Fo should be 30 min (based on process lethality during the decontamination

cycle).

6.6.4.3

No

growth should observe in exposed biological indicators after incubation at

specified temperature and duration. The positive control should show growth

after incubation.

6.6.4.4

The

pressure during decontamination hold period should be between 1.1 - 1.2

Kg/cm².

6.6.4.5

Record

the observations and results in the enclosed Annexure - II.

6.6.5

Photographic Representation Location of temperature sensor and biological

indicator

6.6.5.1

Petriplate and bottle load

External

Sensor

Biological Indicator Strip

6.6.6

Justification

for the probe location

|

Sr.No |

Load Description |

Probe No |

Probe Location |

Justification |

|

01 |

Empty

Cycle |

01 |

Lower frame left side |

Inside Chamber to monitor

temperature profile at Lower frame left side |

|

02 |

Lower frame right side |

Inside Chamber to monitor

temperature profile at Lower frame right side |

||

|

03 |

Middle of chamber |

Inside Chamber to monitor

temperature profile at Middle of chamber |

||

|

04 |

Middle of chamber |

Inside

Chamber to monitor temperature profile at Middle of chamber |

||

|

05 |

Upper frame in the middle |

Inside

Chamber to monitor temperature profile at Upper frame in the middle |

||

|

06 |

Inside chamber with external probe |

Inside Chamber to monitor

temperature profile at Inside chamber with

external probe |

||

|

02 |

Petriplate

and bottle load (Media

Load- 1) |

01 |

Lower frame inside the

Petriplates |

Inside

the load to monitor temperature profile at Lower frame inside the Petriplates |

|

02 |

Upper frame inside the Bottle |

Inside

the load to monitor temperature profile at Upper frame inside the Bottle |

||

|

03 |

Upper frame near the Spreader |

Inside

the load to monitor temperature profile at Upper frame near the Spreader |

||

|

04 |

Upper frame inside Test tube |

Inside

the load to monitor temperature profile at Upper frame near the Spreader |

||

|

05 |

Upper frame inside Sterility canisters |

Inside the load to monitor

temperature profile at Upper frame inside Sterility canisters |

||

|

06 |

Inside Chamber with external

probe |

Inside

Chamber With RTDs to monitor temperature profile at Inside Chamber with

external probe |

||

|

03 |

Test

tubes and bottle load (Media

Load- 2) |

01 |

Upper frame inside the Large Test tubes |

Inside the load to monitor

temperature profile at Upper frame inside the Large Test tubes |

|

02 |

Upper frame inside the bottle |

Inside

the load to monitor temperature profile at Upper frame inside the bottle |

||

|

03 |

Upper frame inside Spreader |

Inside

the load to monitor temperature profile at Upper frame inside Spreader |

||

|

04 |

Lower frame inside the small test

tubes |

Inside

the load to monitor temperature profile at Lower frame inside the small test

tubes |

||

|

05 |

Lower frame Inside Sterility

Canister |

Inside

the load to monitor temperature profile at Lower frame Inside Sterility

Canister |

||

|

06 |

Inside Chamber with external

probe |

Inside

Chamber With RTDs to monitor temperature profile at Inside Chamber with

external probe |

6.7

Developmental Approach Study

6.7.1

Developmental studies shall be

carried out for assessing the parameters at different set parameters and time

intervals to achieve the predefined objective/approach.

6.7.2

The developmental study to be

continued up to achieving of the defined goal,

6.7.3

After achieving the defined goal the

cycle shall be repeated 3 times to validate the defined parameters or changes

in load or process.

6.7.4

The complete details of the

developmental study shall be recorded in Annexure - III

7.0

Discrepancy and corrective Action Report

Any

discrepancies observed during the validation of the equipment shall be

justified in the summary report. Corrective actions of the same shall also be

included. For resolving the discrepancy an action plan shall be developed.

8.0

References

SOP on operation,

Calibration, Cleaning and Maintenance of Vertical autoclave.

9.0

Summary

The validation

report shall include a summary of validation activities describing the

following in brief

9.1

Protocol reference

9.2

Dates of validation activities

9.3

Confirmation of calibration and

preventive maintenance status of instruments, probes and Vertical Autoclave.

9.4

Heat Distribution Study

9.5

Heat Penetration Study

9.6

Brief on result obtained

9.7

Log reduction of Biological

Indicators

10.0

Conclusion

The validation report

shall include statement for conclusion of the validation activity based on

result and observation from the validation activity.

11.0

Attachment

The following

are the attachments which shall be used for collecting and evaluating the raw

data.

|

Sr. No |

Test data sheet |

Title |

Pages |

|

1 |

Annexure – I |

Empty

Chamber Heat Distribution |

5 Pages |

|

2 |

Annexure – II |

Loaded

Chamber Heat Penetration |

6 Pages |

|

3 |

Annexure – III |

Developmental

Approach Study |

5 Pages |

12.0

Revalidation Criteria

Revalidation

criteria is as follows

·

If any major changes or modification in

the system.

·

If any Major changes have been done in

the respective room or module, which is affecting the environmental condition.

·

If there is a contamination problem.

·

At the time of relocation or

Re-qualification.

·

At an yearly frequency as per schedule.

13.0

Revision History

|

Document No. |

Effective Date |

Nature of Change/ Reason for

Revision |

|

PRT/VL/VAC/01/00 |

20-07-2013 |

1

New Protocol |

|

PRT/VL/VAC/01/01 |

22-07-2014 |

1

Removal of typographical error 2

Introduction of validation Matrix 3

Addition of the Developmental

Approach Study 4

Explanation of Procedure i.e. a)

Changes of the decontamination set

temperature from 1220C to

121.1 and b)

Replacement of the word decontamination

with decontamination. |

No comments:

Post a Comment

Pharmaceutical guideline only